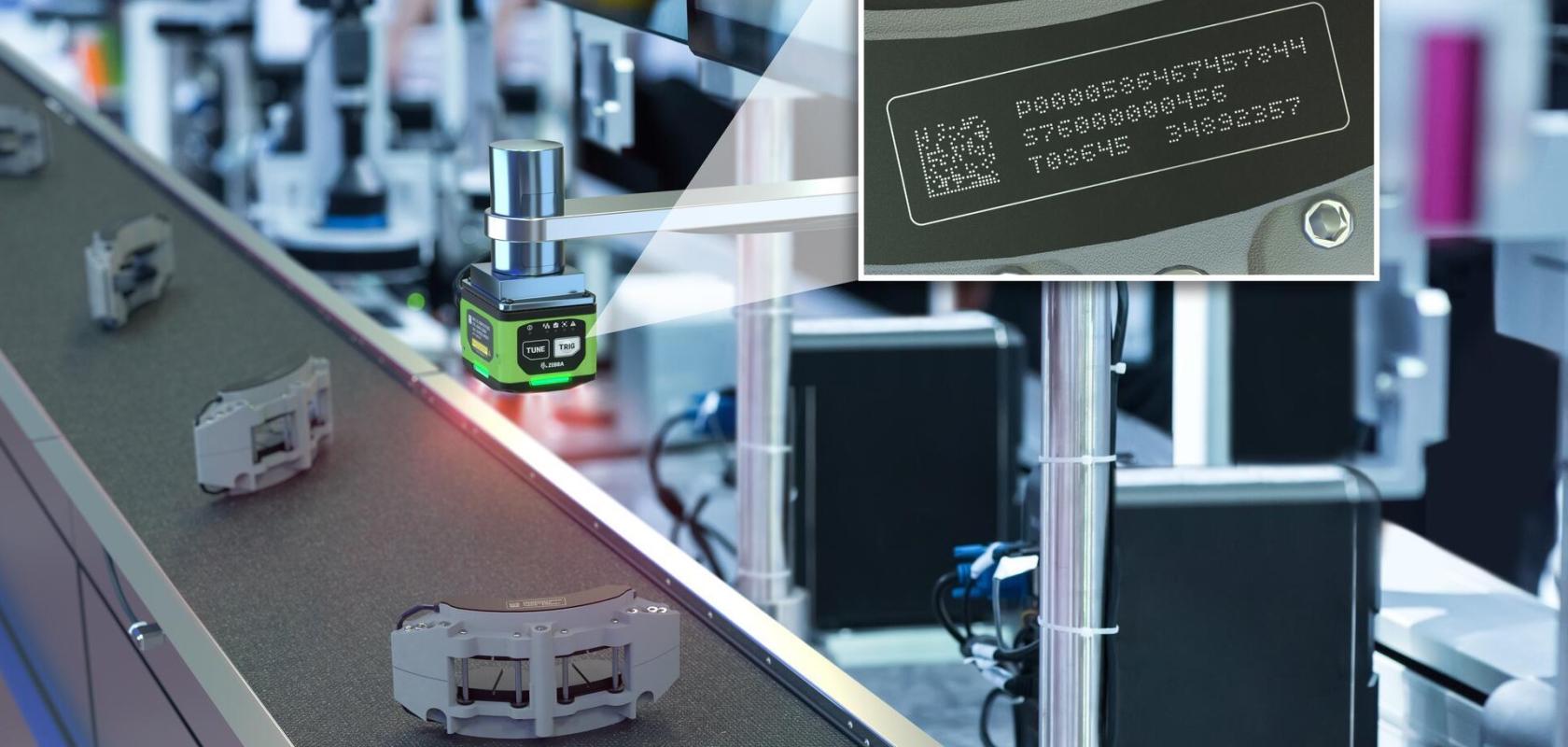

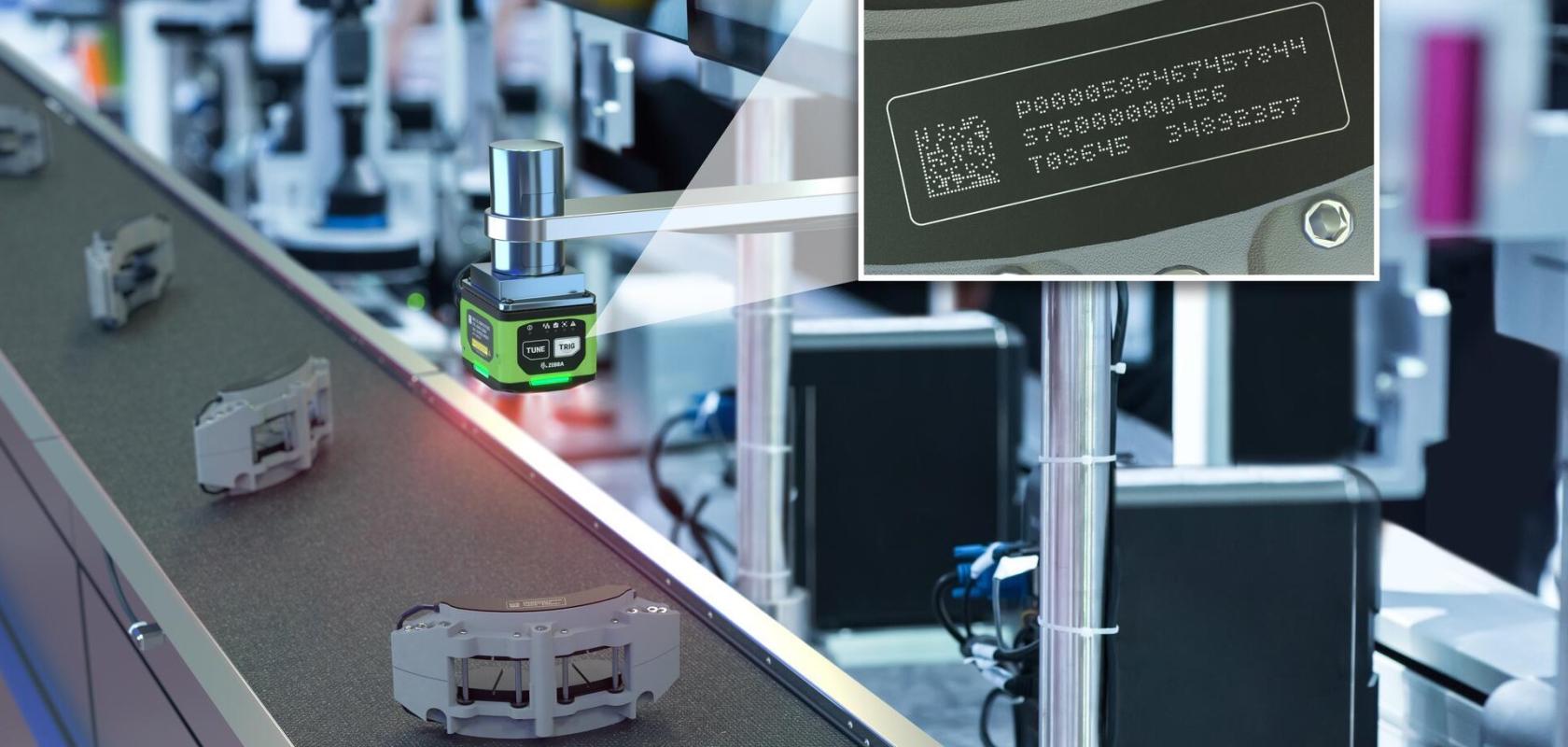

Optical Character Recognition (OCR) can be used to inspect text including best-before-dates, serial numbers, lot numbers, and vehicle identification numbers.

Copyright: imveurope.com – “Deep Learning Brings Optical Character Recognition Into Focus”

Ivar Keulers shares how new, innovative OCR tools are helping eliminate training time and ensure stability across a wide range of industrial use cases

Optical character recognition (OCR) isn’t a new technology. It’s been around since the 1960s and saw a resurgence since the 1990s. It’s a useful and needed tool for inspecting best-before-dates, serial numbers, lot numbers, and vehicle identification numbers (VINs) to ensure the correct components and parts are in the right place at the right time for the right model of vehicle.

However, the problems using OCR tools are also familiar. They need a lot of training time, can be unstable when faced with a change in environment, and don’t handle complex use cases well. Many OCR tools require manufacturers to invest a lot of time for something that is at best ‘okay’ and struggles to read obscure and damaged characters, engraved and embossed formats, characters on reflective and curved surfaces, or changing and harsh lighting conditions.

The challenges around much of today’s OCR are reflected in wider challenges with legacy machine vision systems. Setting up and managing industrial automation inside a manufacturing plant, for example, is often slow and difficult due to the reliance on multiple devices running different software with often old, antiquated user interfaces. The operational challenges around older machine vision systems also remain. These include hardware and software compatibility, financial costs, procurement times, maintenance, lack of interoperability, training and limitations when handling complex use cases.

Thank you for reading this post, don't forget to subscribe to our AI NAVIGATOR!

Many vendors also utilise completely different software for their fixed industrial scanners and machine vision systems, which makes it all hard and costly for their customers to navigate. That runs counter to the core principles of scalability, longevity and compatibility that we apply across all portfolios, especially our mobility, scanning, and automation platforms.

Manufacturing industries have evolved. Production volume and speed keep going up, new safety and regulatory compliance measures must be met, the volume of data grows and needs to be sifted and turned into useful business insights. Manufacturers need modern machine vision solutions that can meet these challenges.

Enter AI-powered machine vision

Forward-thinking manufacturers are increasingly turning to the capabilities provided by artificial intelligence (AI), specifically a subset of machine learning called deep learning, in their machine vision applications. A recent global survey[1] of original equipment manufacturers in the automotive industry found that 24% are using machine vision today, with 44% planning to use it by 2027. That’s a significant 83% increase. A 70% jump was also seen around current use (27%) and future use (46%) of machine learning.

The benefits of machine vision are clearly seen in industries that require higher levels of safety, quality, compliance and efficiency at speed, including automotive, food and beverage, pharmaceutical, and electronic manufacturing.[…]

Read more: www.imveurope.com

Optical Character Recognition (OCR) can be used to inspect text including best-before-dates, serial numbers, lot numbers, and vehicle identification numbers.

Copyright: imveurope.com – “Deep Learning Brings Optical Character Recognition Into Focus”

Ivar Keulers shares how new, innovative OCR tools are helping eliminate training time and ensure stability across a wide range of industrial use cases

Optical character recognition (OCR) isn’t a new technology. It’s been around since the 1960s and saw a resurgence since the 1990s. It’s a useful and needed tool for inspecting best-before-dates, serial numbers, lot numbers, and vehicle identification numbers (VINs) to ensure the correct components and parts are in the right place at the right time for the right model of vehicle.

However, the problems using OCR tools are also familiar. They need a lot of training time, can be unstable when faced with a change in environment, and don’t handle complex use cases well. Many OCR tools require manufacturers to invest a lot of time for something that is at best ‘okay’ and struggles to read obscure and damaged characters, engraved and embossed formats, characters on reflective and curved surfaces, or changing and harsh lighting conditions.

The challenges around much of today’s OCR are reflected in wider challenges with legacy machine vision systems. Setting up and managing industrial automation inside a manufacturing plant, for example, is often slow and difficult due to the reliance on multiple devices running different software with often old, antiquated user interfaces. The operational challenges around older machine vision systems also remain. These include hardware and software compatibility, financial costs, procurement times, maintenance, lack of interoperability, training and limitations when handling complex use cases.

Thank you for reading this post, don't forget to subscribe to our AI NAVIGATOR!

Many vendors also utilise completely different software for their fixed industrial scanners and machine vision systems, which makes it all hard and costly for their customers to navigate. That runs counter to the core principles of scalability, longevity and compatibility that we apply across all portfolios, especially our mobility, scanning, and automation platforms.

Manufacturing industries have evolved. Production volume and speed keep going up, new safety and regulatory compliance measures must be met, the volume of data grows and needs to be sifted and turned into useful business insights. Manufacturers need modern machine vision solutions that can meet these challenges.

Enter AI-powered machine vision

Forward-thinking manufacturers are increasingly turning to the capabilities provided by artificial intelligence (AI), specifically a subset of machine learning called deep learning, in their machine vision applications. A recent global survey[1] of original equipment manufacturers in the automotive industry found that 24% are using machine vision today, with 44% planning to use it by 2027. That’s a significant 83% increase. A 70% jump was also seen around current use (27%) and future use (46%) of machine learning.

The benefits of machine vision are clearly seen in industries that require higher levels of safety, quality, compliance and efficiency at speed, including automotive, food and beverage, pharmaceutical, and electronic manufacturing.[…]

Read more: www.imveurope.com

Share this: